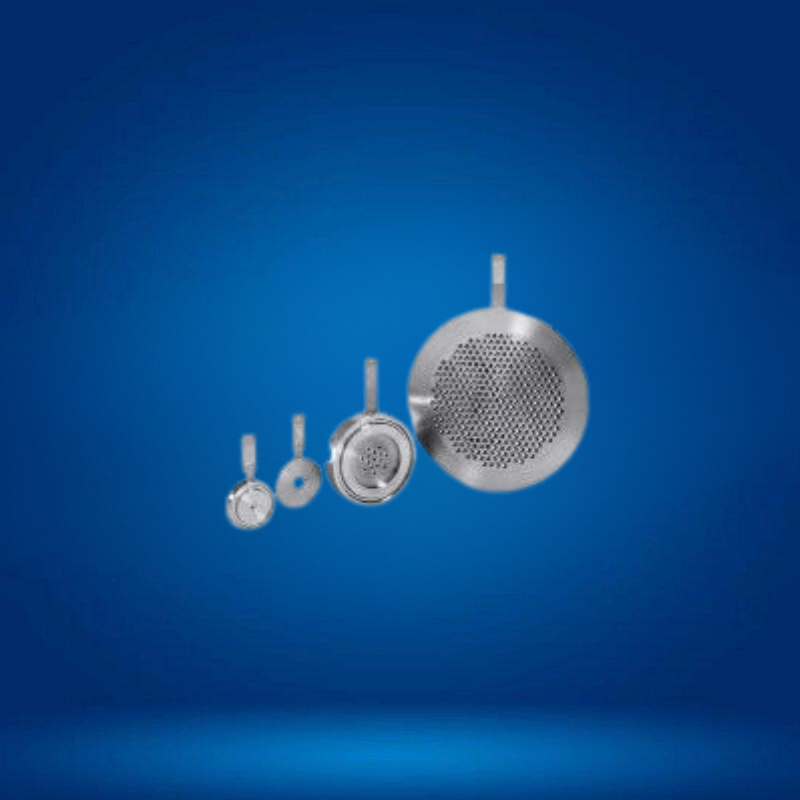

Orifice Plates/Devices

Restriction Orifice Plates and Critical Flow Devices

The calculation, construction and application for pressure control and flow limitation

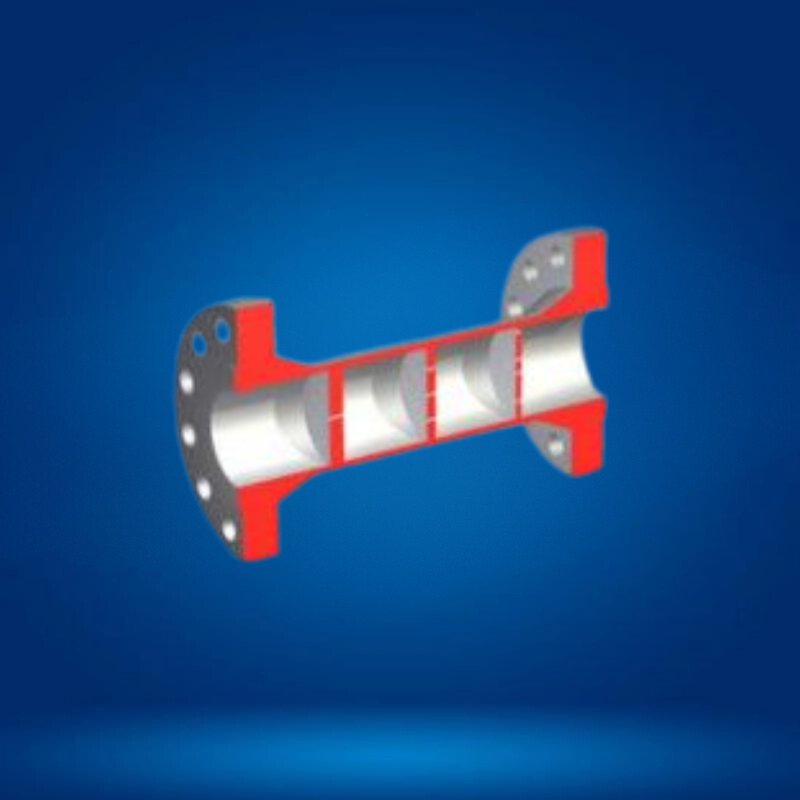

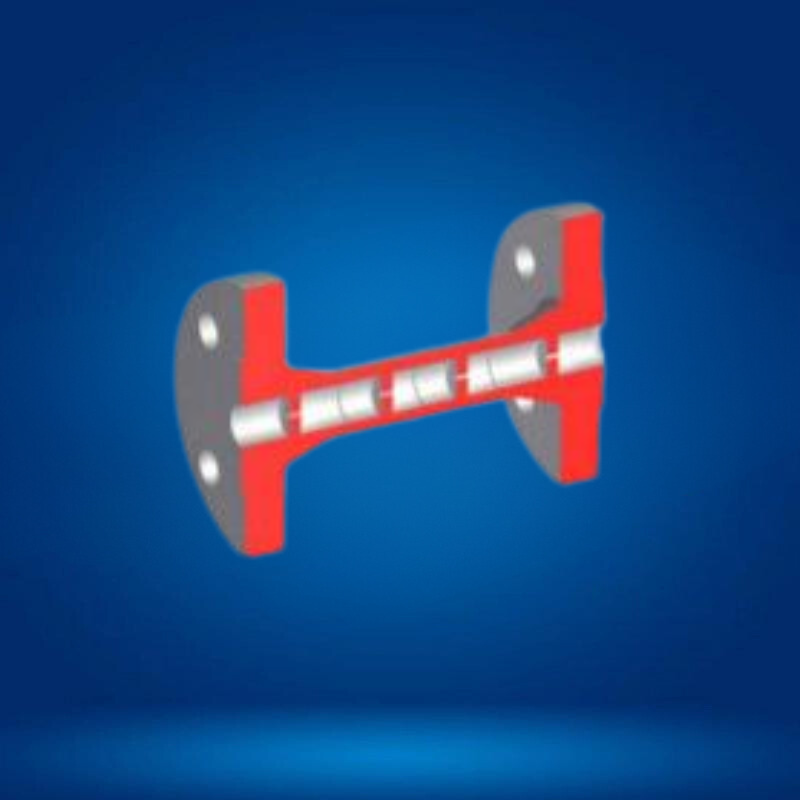

Flow measurement of liquid, gas and steam according to the differential pressure principle has been recognised principle for very many years using orifice plates, venturi tubes and flow nozzles. A restriction in the pipe line creates a pressure drop if the fluid flows. The pressure drop is determined by the velocity of the fluid. The method is thoroughly described in many standards, practices and books. Orifice plates can also bee used for pressure control and flow limitation. This special use is not covered by international standards and is only scaresly mentioned in…