DP Primary Elements

Differential Pressure Primary Elements

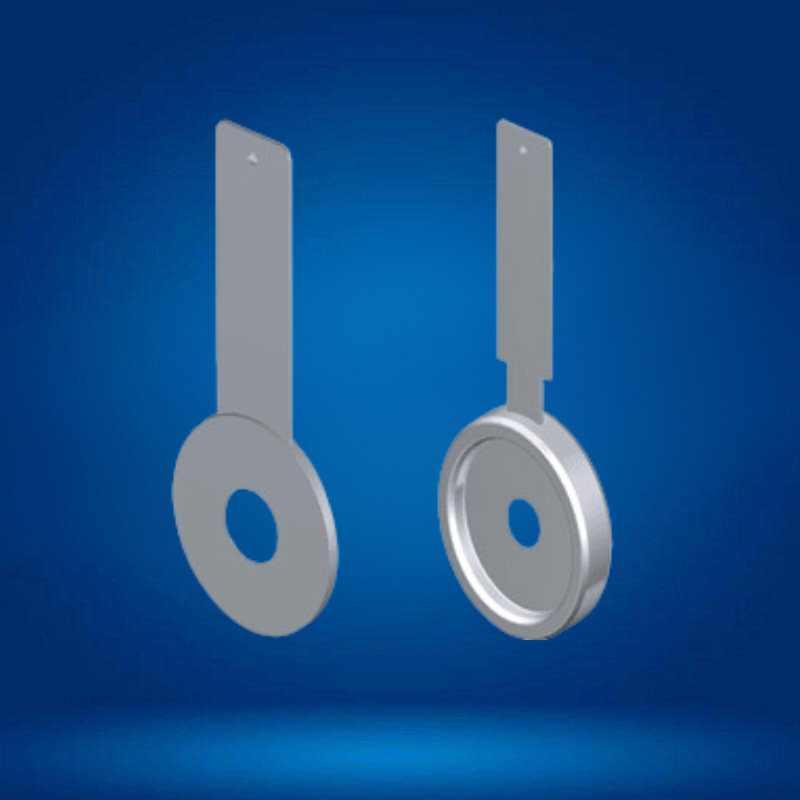

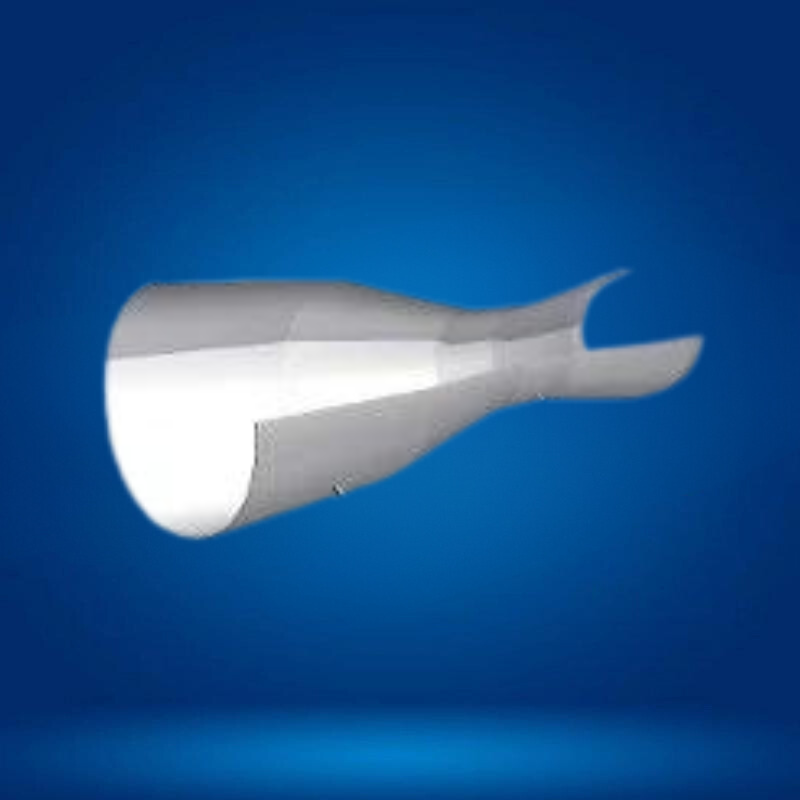

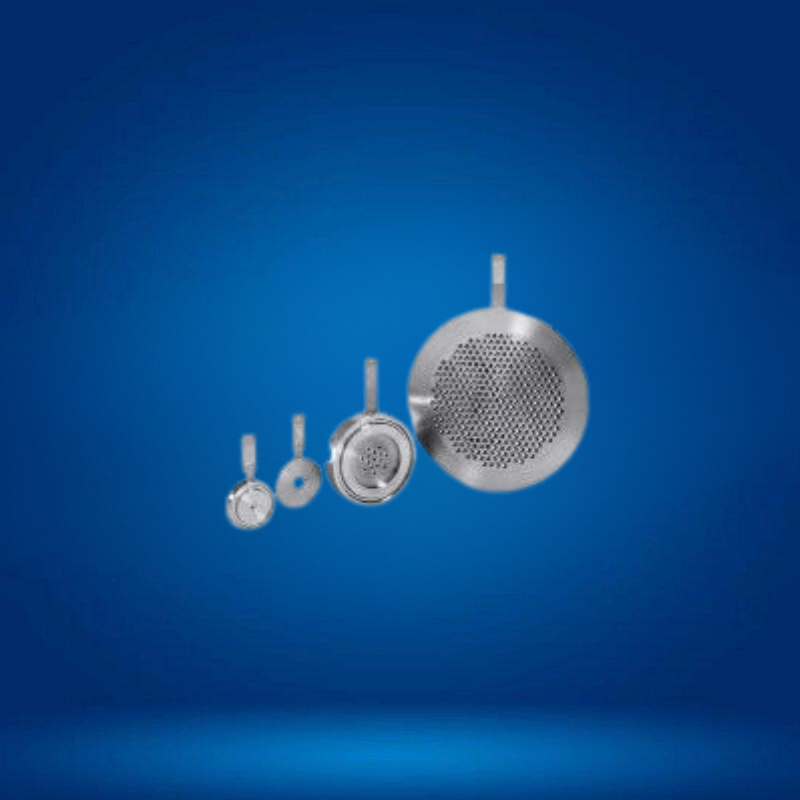

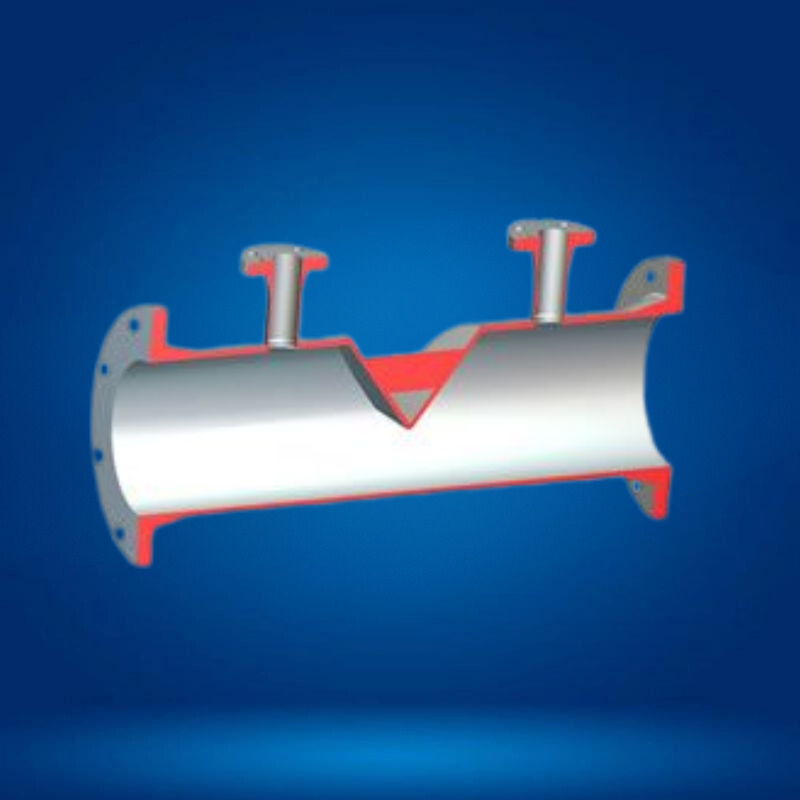

DP-Flow's primary element range are based on the fundamentals of flow measurement flow technologies and are recognized as quality manufactured process control products including primary flow devices for flow measurement. They incorporate primary devices with remote mounted dp cells for a packaged flow metering system, easily installed in to your pipework. They are suitable for use on liquid, gas and steam piping systems, and can be supplied as pressure and temperature compensated systems either with a single multivariable transmitter, or with separate sensors and a mass flow computer. these styles incorporate orifice plate, venturi and nozzles, wedge meter, cone meters, and pitot tubes metering tec…