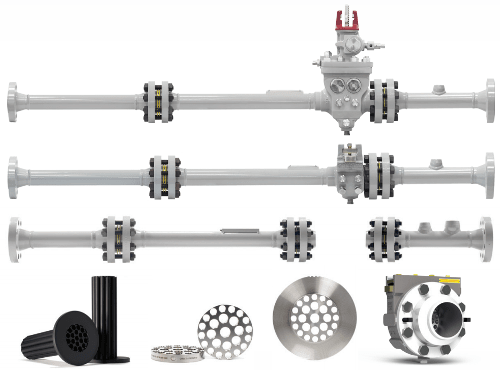

Custom Meter Run

Fabricated custom meter runs for all of our orifice fitting models and a variety of other metering applications. Whether the size is 2” or 30”, high or low pressure, wet, dry or corrosive service, we can put together a custom meter run package that meets your specification or performance needs and perfectly matches your Fitting or other specialized metering device.

Flow Conditioning Accessories

The goal of meter run design is to account for swirl and turbulence. From traditional 19-tube bundle straightening vanes in carbon or stainless steel, to the compact Zanker or #50-style Flow Conditioners and Flow Conditioner Housings, we will help you develop the flow profile you need to achieve maximum performance and accuracy in the field.

End Connection Option

Meter Runs can be fabricated with a variety of standard tube ends. All inner surface welds are precision ground and inspected to meet exacting I.D. surface and roundness tolerances. Per your requirements, two and three-piece meter runs can have dissimilar end types up and downstream of the orifice fitting.

Welding Standard

Each Meter Run is professionally fabricated by our team of certified “B” Pressure Welders and experienced pipe finishers to meet and exceed the stringent specifications of AGA / API / ISO. Our welding procedures are registered with the Alberta Boiler and Safety Association (ABSA) and are in accordance with the applicable ASME Boiler and Pressure Vessel Codes. We will ensure that all of your NDT and stress relieving requirements are met with full documentation.

Branch Connection Options

Industry standard offerings provide one 1” and one 3/4” branch connection on the downstream spool. Our custom meter tube design capability allows us to fabricate nearly any combination of weldolets, sockolets, flanged outlets, threadolets and latrolets in any size and orientation.

Meter Run Specification Plate

All Meter Runs include a specification plate mounted immediately upstream of the orifice fitting. These spec plates detail pipe schedule, pressure rating, maximum beta, maximum orifice and other information essential to proper operation.