Orimas Mass Flow Meters

OR1; OR2

The EMCO Orimas mass flow compact orifice flow meter

Benefits

- Sizes ranging from DN 40 (1½") up to DN 400 (16").

- Standardised product based on well proven and widely accepted technology.

- No moving parts. Not sensitive to vibrations. Compact design. Easy to install. High accuracy.

Typical Applications

The ORIMAS mass flow meters measure the mass flow of most liquids and gases within the process industries, including chemical, petro-chemical, pharmaceutical and the power industry. The ORIMAS is based on the principle of measuring velocity, the static pressure and the temperature in the pipe line. The electronics computerise the mass flow by using the 3 measured values. The ORIMAS flow meters are backed by international standards covering flow calculation, manufacturing tolerances, accuracy and installation requirements. This type of bare bone technology is world wide accepted and supported by millions of successful installations.

The Orimas flow meter features are:

- Standardised product based on well proven technology.

- Compact design.

- Simple construction.

- Free choice for horizontal or vertical pipe run.

- Standardised construction means low inventory.

- No moving parts.

- Not sensitive to vibrations.

- The electronics delivers output signal linear to mass flow.

- Digital indicator for local mass flow reading.

- High accuracy.

- Wide rangeability.

- Easy to install.

- Easy to re-calibrate.

- Full PED compliance PED 97/23 EC

Construction

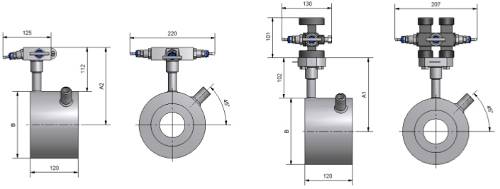

Model Model OR1

The Orimas flow meter model OR1 consists of a primary element based on the differential pressure principle, a 3 valve manifold valve a multivariable transmitter and a temperature sensor. The multi variable transmitter measures the differential pressure, the static pressure and has an input connection to the temperature sensor. The flow computer housed in the transmitter performs the dynamic flow calculation.

Model OR2

The ORIMAS flow meter model OR2 consists of a primary element

and operates as mentioned above but has an integrated 3 valve manifold. The ORIMAS flow meter is mounted between flanges in sizes from DN 40 (11⁄2") to DN 400 (16") in pressure ratings up to PN 40 (300 lbs). Other sizes and pressure ratings on request.

Accessories

Remote Mounting Kit type RMK is available if remote mounting of electronics is required in case of difficulty accessibling pipeline or if there are elevated process temperatures.

The customer has to provide the stainless steel instrument tube Ø 12 x 1 mm between flow meter and electronics. Remote electronic indicator witd LCD is available for local flow indication and if required check/change of flow rate (differential pressure).

Principle of Measurement

The ORIMAS is a mass flow meter

A restriction in a pipe line changes the value of the different energies.

Based on the law of energy balance developed by Bernoulli the sum of energies remains constant.

Increases the velocity in the pipe line decreases the pressure in the restriction.

The pressure differential between the inlet pressure and the pressure in the restriction is measured and expressed as the flow velocity.

The static pressure and the temperature is measured.

When the physical values of the fluid is known and the inner pipe diameter is established the electronics calculate the mass flow. The mass flow is expressed in an analogue signal 4 - 20 mA or signal for digital communication.

Technical Data

- Sizes : DN 40 - DN 400, 11⁄2" - 16", larger sizes on request

- Pressure rating : up to PN 40, 300 lbs, higher pressure ratings on request

- Temperature : Process : -50 - +150°C,

- higher temperature witd Remote Mounting Kit

- Mounting style : Between flanges according to DIN or ANSI standards

- Flange facing : flat face (standard), raised face, DIN 2512 N, DIN 2513 R

- Overall lengtd : 120 mm

- Material : Stainless steel AISI 316, others on request

- Design and calculation standards : ISO 5167, ASME MFC-3M.

- Vent or drain hole : On request

- β (d/D) : 0,5 and 0,6; other β on request.

- Accuracy : +/- 1 %

- Rangeability : 8:1

- Repeatability : better tdan 0,1 %

- Pressure loss : typical 150 mbar for liquid flow, and 50 mbar for gas flow (values are given at full flow)

- Reynolds No : Re > 5000

- Allowable differential pressure : max 2,5 bar

- Output signal : analogue 4 - 20 mA or Digital communication via protocol, HART, PROFIBUS, Fieldbus Foundation or others.

- Local indicator (option): LCD showing flowing units or %

- Power supply : 14 - 36 Vdc, typical 24 Vdc.

- Max load (24 Vdc) : 700 Ohm

- Enclosure : IP 67

- Ex protection : intrinsically safe EEx ia IIC T6,Explosion proof EEx d IIC T6

- Temperature : Ambient : -40 - +80°C

Sizes

DIN Flanges

| Size; | Pipe OD | Pressure rating | Inner pipe diameter | ß = 0,5 Bore | ß = 0,6 Bore | B | A1 | A2 |

|---|---|---|---|---|---|---|---|---|

| DN 40 | 48,3 | PN 40 | 43,1 | 21,5 | 26,0 | 90 | 147 | 157 |

| DN 50 | 60,3 | PN 40 | 54,5 | 27,3 | 32,0 | 107 | 156 | 166 |

| DN 65 | 76,1 | PN 40 | 70,3 | 35,0 | 42,0 | 127 | 166 | 176 |

| DN 80 | 88,9 | PN 40 | 82,5 | 41,0 | 49,5 | 142 | 173 | 183 |

| DN 100 | 114,3 | PN 16 | 107,1 | 54,0 | 64,0 | 162 | 183 | 193 |

| DN 100 | 114,3 | PN 40 | 107,1 | 54,0 | 64,0 | 168 | 186 | 196 |

| DN 125 | 139,7 | PN 16 | 131,7 | 66,0 | 79,0 | 192 | 198 | 208 |

| DN 125 | 139,7 | PN 40 | 131,7 | 66,0 | 79,0 | 194 | 199 | 209 |

| DN 150 | 168,3 | PN 16 | 159,3 | 80,0 | 96,0 | 218 | 211 | 221 |

| DN 150 | 168,3 | PN 40 | 159,3 | 80,0 | 96,0 | 224 | 214 | 224 |

| DN 200 | 219,1 | PN 16 | 207,3 | 104,0 | 124,4 | 273 | 239 | 249 |

| DN 200 | 219,1 | PN 25 | 206,5 | 104,0 | 124,4 | 284 | 244 | 254 |

| DN 200 | 219,1 | PN 40 | 206,5 | 104,0 | 124,4 | 290 | 247 | 257 |

| DN 250 | 273 | PN 16 | 260,4 | 130,0 | 156,0 | 329 | 267 | 277 |

| DN 250 | 273 | PN 25 | 258,8 | 130,0 | 156,0 | 340 | 272 | 282 |

| DN 250 | 273 | PN 40 | 258,8 | 130,0 | 156,0 | 352 | 278 | 288 |

| DN 300 | 323,9 | PN 10 | 309,7 | 155,0 | 185,0 | 378 | 291 | 301 |

| DN 300 | 323,9 | PN 16 | 309,7 | 155,0 | 185,0 | 384 | 294 | 304 |

| DN 300 | 323,9 | PN 25 | 307,9 | 155,0 | 185,0 | 400 | 302 | 312 |

| DN 300 | 323,9 | PN 40 | 307,9 | 155,0 | 185,0 | 417 | 311 | 321 |

| DN 350 | 355,6 | PN 10 | 341,4 | 170,0 | 204,0 | 438 | 321 | 331 |

| DN 350 | 355,6 | PN 16 | 339,6 | 170,0 | 204,0 | 444 | 324 | 334 |

| DN 350 | 355,6 | PN 25 | 339,6 | 170,0 | 204,0 | 457 | 331 | 341 |

| DN 350 | 355,6 | PN 40 | 338,0 | 170,0 | 204,0 | 474 | 339 | 349 |

| DN 400 | 406,4 | PN 10 | 392,2 | 195,0 | 234,0 | 489 | 341 | 351 |

| DN 400 | 406,4 | PN 16 | 390,4 | 195,0 | 234,0 | 495 | 350 | 360 |

| DN 400 | 406,4 | PN 25 | 388,8 | 195,0 | 234,0 | 514 | 359 | 369 |

| DN 400 | 406,4 | PN 40 | 384,4 | 195,0 | 234,0 | 546 | 375 | 385 |

ANSI flanges

| Size | Pipe OD | Pressure rating | Sch. 10S Inner Diameter | Sch. 40 Inner Diameter | Sch. 80 Inner Diameter | ß=05 Bore. | ß=06 Bore. | B | A1 | A2 |

| dia. | dia. | dia. | ||||||||

| 11⁄2" | 48,3 | 150lbs | 42,7 | 40,9 | 37,3 | 20,0 | 24,0 | 85,7 | 145 | 155 |

| 300lbs | 95,3 | 150 | 160 | |||||||

| 2" | 60,3 | 150lbs | 54,7 | 52,5 | 49,3 | 26,0 | 31,5 | 104,8 | 154 | 164 |

| 300lbs | 111,1 | 158 | 168 | |||||||

| 3" | 88,9 | 150lbs | 82,8 | 77,9 | 73,7 | 39,0 | 47,0 | 136,5 | 170 | 180 |

| 300lbs | 149,1 | 177 | 187 | |||||||

| 4" | 114,3 | 150lbs | 108,2 | 102,3 | 97,2 | 51,0 | 61,0 | 174,6 | 189 | 199 |

| 300lbs | 181,1 | 193 | 203 | |||||||

| 6" | 168,3 | 150lbs | 161,5 | 154,1 | 146,3 | 77,0 | 92,5 | 222,3 | 213 | 223 |

| 300lbs | 279,4 | 242 | 252 | |||||||

| 8" | 219,1 | 150lbs | 211,5 | 202,7 | 193,7 | 101,0 | 121,6 | 279,4 | 242 | 252 |

| 300lbs | 308 | 256 | 266 | |||||||

| 10" | 273 | 150lbs | 264,6 | 254,5 | 242,8 | 127,0 | 153,0 | 339,7 | 272 | 282 |

| 300lbs | 362 | 283 | 293 | |||||||

| 12" | 323,9 | 150lbs | 314,7 | 303,2 | 289,1 | 150,0 | 180,0 | 409,6 | 307 | 317 |

| 300lbs | 422,3 | 313 | 323 | |||||||

| 14" | 355,6 | 150lbs | 346 | 333,3 | 317,5 | 165,0 | 198,0 | 450,9 | 327 | 337 |

| 300lbs | 485,8 | 345 | 355 | |||||||

| 16" | 406,4 | 150lbs | 396,8 | 381 | 363,6 | 190,0 | 228,0 | 514,4 | 359 | 369 |

| 300lbs | 539,8 | 372 | 382 |

Overall dimensions

Installation Requirements

The Orimas flow meter can be mounted in a horizontal or vertical pipe. For liquid flow in a horizontal pipe the electronics shall be mounted below the pipe. For gas flow in a horizontal pipe the electronics shall be mounted above the pipe. To insure high accuracy of measurement, long straight pipe runs up-stream from the flow meter is necessary. The required straight pipe run depends on the disturbance upstream. To maintain the 1% accuracy the minimum straight pipe run upstream shall be 14 x inner pipe diameter and 6 x downstream If an additional inaccuracy of 1⁄2 % is acceptable the required straight pipe runs are reduced to half of the above values. Saturated and superheated steam is covered by STEEMCO flow meters.

Typical Applications

Fast and easy installation in liquid and gas lines requiring minimal interuptions for calibration.

Orimas Coding

1. Type

| In AISI 316 witd | code OR1 |

| transmitter flange integrated manifold | code OR2 |

| 2. Size | |

|---|---|

| DN 40 DIN standard | code 040 |

| DN 50 DIN standard | code 050 |

| DN 65 DIN standard | code 065 |

| DN 80 DIN standard | code 080 |

| DN 100 DIN standard | code 100 |

| DN 125 DIN standard | code 125 |

| DN 150 DIN standard | code 150 |

| DN 200 DIN standard | code 200 |

| DN 250 DIN standard | code 250 |

| DN 300 DIN standard | code 300 |

| DN 350 DIN standard | code 350 |

| DN 400 DIN standard | code 400 |

| 11⁄2” ANSI standard | code 01.5 |

| 2” ANSI standard | code 002 |

| 3” ANSI standard | code 003 |

| 4” ANSI standard | code 004 |

| 6” ANSI standard | code 006 |

| 8” ANSI standard | code 008 |

| 10” ANSI standard | code 010 |

| 12” ANSI standard | code 012 |

| 14” ANSI standard | code 014 |

| 16” ANSI standard | code 016 |

| 3. Pressure rating | |

| PN 10 DIN standard | code 10 |

| PN 16 DIN standard | code 16 |

| PN 25 DIN standard | code 25 |

| PN 40 DIN standard | code 40 |

| 150 lbs ANSI standard | code 15 |

| 300 lbs ANSI standard | code 30 |

| 4. Facing | |

| DIN 2526 Form A | code 26 |

| DIN 2513 Form R13 | code 13 |

| DIN 2512 Form N | code 12 |

| Raised face RF ANSI standard | code RF |

| Flat face FF ANSI standard | code FF |

| 5. Pipe schedule ( only applicable for ANSI flanges) | |

| DIN flanges | code 00 |

| Schedule 10S | code 10 |

| Schedule 40 | code 40 |

| Schedule 80 | code 80 |

| 6. β value | |

| β value 0.5 | code 5 |

| β value 0.6 | code 6 |

| β value free choice | code 9 |

| 7. Drain/vent hole Ø3 mm | |

| Witdout drain/vent hole | code 0 |

| Witd drain/vent hole | code 1 |

| 8. manifold valve | |

| OR1 - Witdout | code 0 |

| OR2 - 3 valve manifold | code 1 |

| OR2 - Integrated 3 valve | code 2 |

| 9. Differential pressure transmitter | |

| Witdout | code 0 |

| Included code Original transmitter type no. | |

| 10. PT100 sensor | |

| 1/1 DIN form B, Alu head | code 0 |

| 1/2 DIN form B, Alu head | code 1 |

| 1/3 DIN form B, Alu head | code 2 |

| 1/1 DIN form B, 316 head | code 3 |

| 1/2 DIN form B, 316 head | code 4 |

| 1/3 DIN form B, 316 head | code 5 |

Examples

DN 100 ORIMAS in stainless steel PN 40 with DIN 2526 facing, β value 0,6, without drain/vent hole and 3 valve type G3H double flanged manifold valve, and without transmitter, but with Pt100 1/1 DIN element in Form B head has following code:

OR1-100-40-26-00-6-0-1-0-08"

ORIMAS in stainless steel 150 lbs with RF facing with β value 0,5, with drain/vent hole, with integrated 3 valve manifold and Yokogawa differential pressure transmitter type EJX 110A has following code:

OR2-008-15-RF-40-5-1-2-EJX110A-0

Works with:-

Differential pressure transmitters:-IDP10; IDP15; IDP25; IDP31; IDP50

And all our Absolute Pressure and Gauge Pressure transmitters, Temperature sensors and mass flow computers.

MultiVariable Transmitters :- IMV25, IMV30

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222

Supplied by DP-Flow