PST Positioner

PST Positioner with SOV Monitoring

Description

A Partial Stroke Test (PST) application with SOV monitoring offers the highest level of safety, in avoiding any spurious trips and testing of the solenoid valve (SOV). Foxboro® provides Partial Stroke Testing Solutions with SRD991 and SRD960 positioners for Safety Systems and Emergency Shutdown (ESD) applications.

Business Value

With more than 50 years experience in valve positioners, Foxboro offers the most complete line of instrumentation available from pneumatic and analogue devices to the most advanced smart positioners with Hart®, Profibus or Fieldbus communication. The proven reliability and robustness of Foxboro positioners helps to improve process performance, providing predictive maintenance and Advanced Diagnostics.

Benefits

- Test interval of the ESD valves extended up to 5 years

- Increased safety in testing the SOV

- Spurious Trip kept to the lowest level

About Foxboro® Valve Positioners

Foxboro has been producing On-Off and Modulating Control valve positioners of the highest quality since 1961 and offers the widest range of valve positioners, from pneumatic and analogue devices to the most advanced smart positioners withHart, Profibus orFieldbus communication, to work alongside any application in any industry.

One particular application is Partial Stroke Testing. PST is a method where the ESD valve is typically moved 10-20% and returned to its original position in a short period of time. As the most common dangerous failure mode in a static ESD valve is “failure to move,” On-line Partial Stroke Testing generated by the smart positioner SRD991 (intrinsic safety application) and SRD960 (Explosion proof application) is the key to safety. Moreover, the PST positioner can offer operators a tool to enable predictive maintenance on the ESD valves with data history and friction analysis. The test can be easily executed via the FDT/DTM based configuration and diagnostic tool VALcare® and Valve Monitor.

Technical Challenge

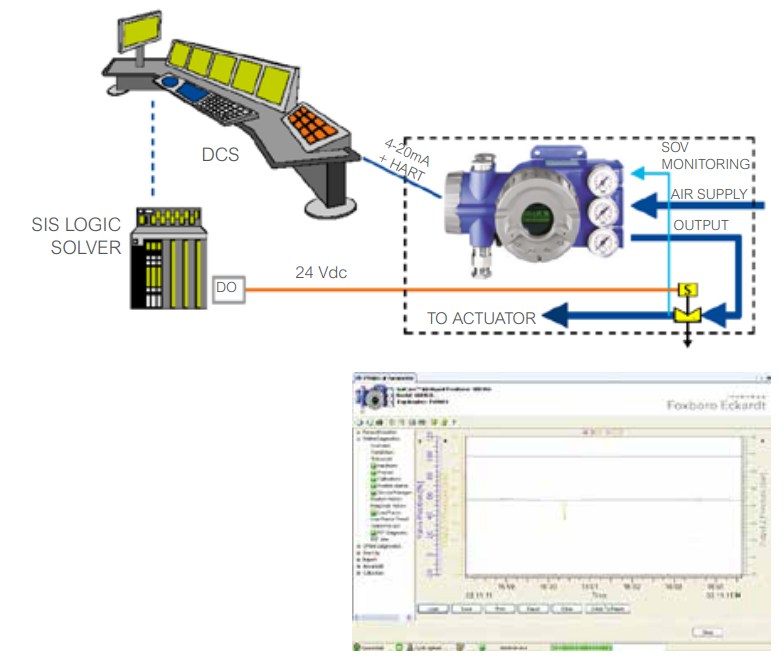

More and more customers want dedicated valve positioners for PST monitoring only, keeping the SOV (solenoid valve) for shutdown. These types of architectures are normally designed to clearly separate the diagnostic functions (normally connected to the DCS) from the safety function (normally connected to SIS). For one particular project, the plant owner wanted to have feedback not only for the valve status (ready to close/about to jam/jammed), but also for the SOV status (ready to switch/jammed): Can the solenoid valve still react or not? This question is critical because it can have a severe impact on the functionality of a safety system and could result in adverse conditions for operators, plant equipment and the environment. In addition, an important requirement is to avoid as far as possible, the risk of a spurious trip from the positioner, even in a case of damage within the electronic board. Indeed, a spurious trip is a costly break in production and it multiplies the risk and the errors linked to any startup. With these challenging requirements from customers, we developed our state-of-the-art PST positioner.

The Foxboro Solution

PST Positioner with SOV Monitoring

Foxboro provides the most complete and the most secure PST solution made with positioners.

Foxboro positioners already offer the standard features for a PST application, with all available parameterization and Premium Diagnostics. The PST status is available under the HART cyclic variable. In addition, the positioner has been pneumatically modified to become Fail Open. So even in a case of electronic damage, the valve will remain open.

Regarding SOV monitoring, the pressure between the solenoid valve and the actuator is measured by the positioner. Therefore, the positioner is able to detect the perturbation of pressure due to a quick test of the SOV. Any small SOV dip higher than 200 ms can be detected by the positioner and it reinitializes a timer. The extreme minimum dip detection time gives confirmation that the solenoid valve is working, keeping the valve in its original position (process not disturbed).

Finally, in case of emergency shutdown, a Full Stroke can be detected and a timer has been developed to measure the time to close.

Results

On critical Emergency Shutdown Valves controlled by a solenoid valve, Foxboro provides a solution to check not only the valve status and the friction of the final element, but also the SOV in charge of cutting air to the actuator in case of emergency shutdown.

Moreover, the positioner is now pneumatically designed not to impair the spurious trip of the final element.

Premium diagnostics, the PST status and the SOV status are available through HART communication. And finally, the cost of implementation has been reduced since it only requires a limited number of input/output from the SIS.

If you require further information on this product or would like a quotation, please contact dp-flow on:

email: sales@dp-flow.co.uk

sales +44(0)1608 544222