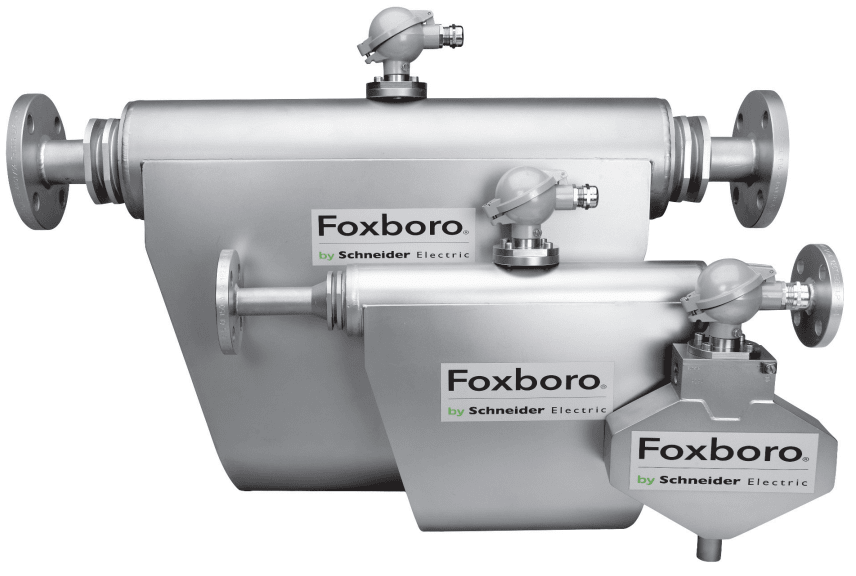

CFS25

Foxboro® brand CFS25 Coriolis flowtubes combine with a Model CFT51 Digital Coriolis Mass Flow Transmitter to form an I/A Series® Coriolis Mass Flow and Density Meter. The principle of Coriolis acceleration is used, which allows true mass flow rate measurements of fluids to be made directly without the need for external temperature, pressure, or specific gravity measurements.

Features

- Economical design is ideally suited for typical applications in the chemical industry

- Precision system achieved using digital signal processing (DSP) transmitter

- High system accuracy: ±0.10% of flow rate plus flowtube zero instability for liquid; and ±0.50% of flowrate plus flowtube zero instability for gas.

- Density accuracy of ±0.0005 g/cc(1) or better.

- Wide rangeability in excess of 100:1 without sacrificing performance.

- All flowtubes are available with a dual-path design (parallel loops). Smaller flowtubes are also available with a single-path design (serial loops) ideal for shear-sensitive fluids and applications requiring positive cleaning.

- Welded 304 stainless steel enclosure.

- Nickel alloy (equivalent to Hastelloy® C-22(2)) construction available on some flowtube sizes.

- Designed for CSA, CSAus, ATEX, and IECEX hazardous area locations. Applicable agency plate also includes the CE mark.

1. With in situ calibration

2. Hastelloy is a registered trademark of Haynes International Inc.

Introduction

This I/A Series Mass Flow and Density Meter, comprising a CFT51 Mass Flow and Density Transmitter and a CFS25 Mass Flowtube, measures fluid mass flow rate directly, not inferentially. The direct measurement of mass eliminates the inaccuracies of multiple process measurements associated with volumetric flow devices are eliminated.

This flowmeter is an advanced generation of mass flow devices using Coriolis principles. It incorporates significant improvements in transmitter and flowtube design, including digital signal processing (DSP), computer modeling, remote communications, automated manufacturing processes, construction and testing that all add up to an ideal product for today and tomorrow's “real world” process fluid flow applications.

Model CFT51 DSP Transmitter

The CFS25 Mass Flowtube is used with the Model CFT51 Digital Coriolis Mass Flow Transmitter to form a mass flow and density meter. The transmitter uses DSP techniques to improve flowmeter performance and to minimize the shortcomings experienced by existing Coriolis flowmeters, such as operation during two-phase flow, partial empty tube conditions, and batching from empty. Refer to PSS 1-2B7 C for further data and specifications relating to the Model CFT51 transmitter.

Application Versatility

This brand of Coriolis flowmeter is insensitive to varying process conditions. In addition to accurately measuring liquid, it can also be used in applications with entrained air, non-Newtonian fluids, viscous and abrasive fluids, slurries, and liquefied gases.

Real World Conditions

Exemplified by:

- High accuracy at realistic nominal velocities means reduced erosion

- Immunity to external pipe vibrations

- Low pressure loss

- High accuracy over a wide range of fluid densities

- Immune to entrained air

-Continues to operate duriing two-phase flow

-No zero drifting with CFT51 DSP transmitter

High Flowtube Reliability

Assured because of:

- Advanced finite element analysis (FEA) technology for flowtube design

- Annealed process-wetted welds

- Hydrostatically tested at 1.5 times the rated maximum pressure

Product Patents

This product and associated components are protected by one or more of the following US patents: 6311136, 6505519, 6507791, 6754594, 6758102, 6917887, 6950760, 6981424, 7124646, 7136761, 7146280, 7404336, 7505854, 7571062, 7784360, 8000906.